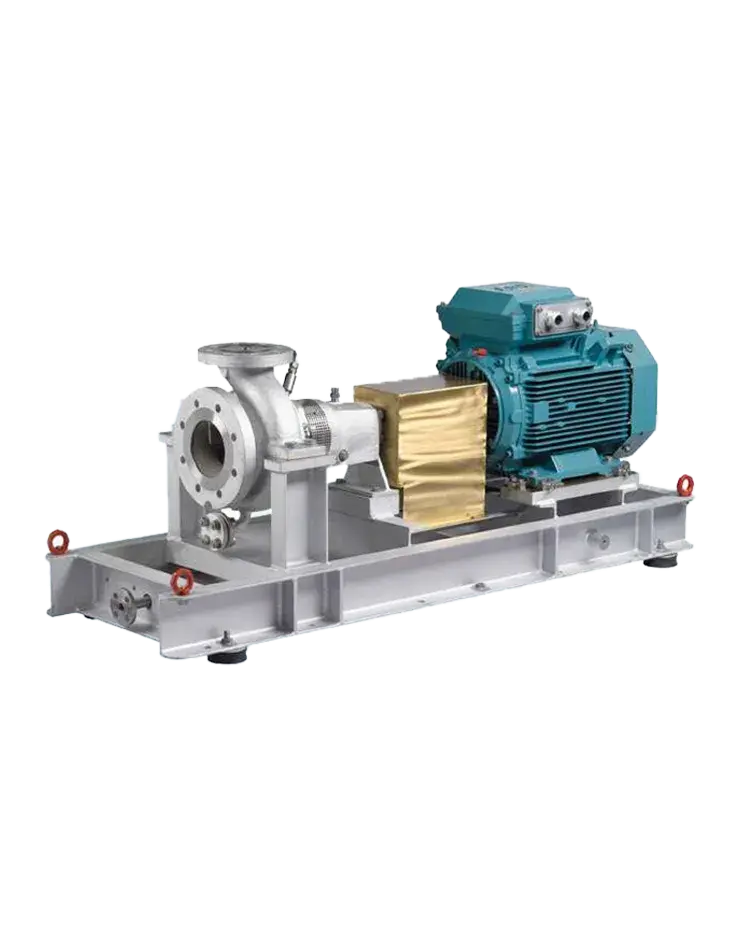

RDZA

API CENTRIFUGAL PUMP

RDZA API CENTRIFUGAL PUMP

Rotodel Pumps Make API Complaint / ISO 13709 Pump which are design &

Manufactured to latest edition both horizontal as well as

vertical pumps . our API Pumps are used widely on offshore ,

oil & gas , Petrochemicals & Power plant in most demanding

Application , Rotodel Pumps Make latest API design Pumps are

engineered & manufactured to customer specification & supplied

on the most competitive lead time in the industries

SPECIFICATIONS

| TECHNICAL DATA | |

|---|---|

| SIZE | UPTO 250 MM SUCTION & DISCHARGE |

| CAPACITY | UP TO 660 M3/HR (11000 LPM) |

| HEAD | UP TO 200 MTR. |

| MATERIAL | C.I. / C.S. / BRONZE / SS-304 & 316 / SS-316 L / ALLOY-20 AND OTHER ALLOYS |

APPLICATIONS

| Condensate Pumps | Diesel / Motor Spirit / Kerosene Decanting | Rail Wagon Unloading |

| Tank Lorry Filling | LPG Filling / Gasoline Service | Refinery / Petroleum |

| Textile | Process Industries | Ethanol Blending |

| Power | Nuclear Plants | Thermal Plants |

| Petrochemicals | Fertilizer Plants | Defence |

| Steel |

MATERIAL OPTIONS

| C.I - IS 210 FG - 20 | C.S - CARBON STEEL ASTM A216 GR. WCB | ACI - ALLOY CAST IRON BR - IS - 318 GR.2 |

| WEAR RINGS (HARDENED) | A-20 - CAST ALLOY - 20 ASTM A296 - CN - 7M | 410 - CAST STAINLESS STEEL ASTM A296 |

| HAST. B - HASTALLOY B | HAST. C - HASTALLOY C |

FEATURES

| ⇥ Centre line discharge. |

| ⇥ Centre line supported Casing (OH2) / Foot Type Casing (OH1). |

| ⇥ Back pull out design. |

| ⇥ Seal chamber to accommodate gland packing. |

| ⇥ Mechanical seals as per API-610/682 design. Can accommodate single/double/cartridge type. |

| ⇥ Confined gaskets. |

| ⇥ API Latest design. |

| ⇥ Dynamically balanced impeller limits vibration and ensures smooth operation over wide Flow range. |

| ⇥ Impeller lock nut with positive lock. |

| ⇥ Shaft threads protected. |

| ⇥ Bearing with cooling systems. |

| ⇥ Class 300 flanges. |

| ⇥ Gland plate with heating arrangement. |

| ⇥ RDZA range has been developed to meet the vigorous need of API Latest design. |

| ⇥ Heavy duty rotating assembly with dynamically balanced impeller, housed in heavy duty steel housing - fitted with antifriction ball and roller bearings. |

| ⇥ To minimize shaft misalignment and longer bearing life, nozzles are designed for heavy loads. |

| ⇥ API 682 Seal Chamber accommodates a wide variety of seal configurations including dual pressurized and unpressurized cartridge types for the most severe service. |